What Design Principles Can Help Improve the Performance of Customized Chromium Carbide Overlay Plates

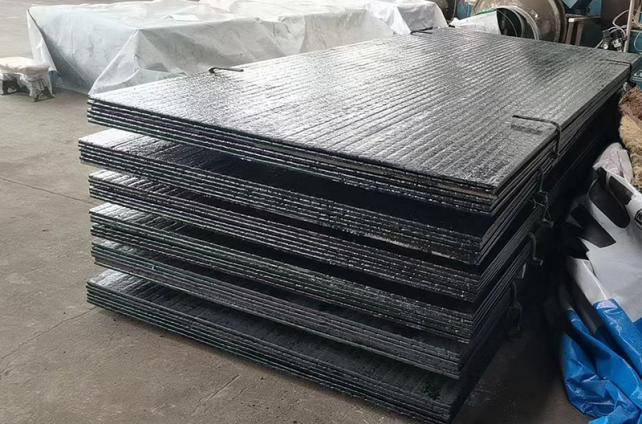

The chromium carbide wear-resistant plate is a composite steel plate manufactured by a special process, and its surface is covered with one or more layers of wear-resistant alloy layers rich in chromium carbide. During the manufacturing process, following some design principles can significantly improve its performance. The following are several key design principles.

1. Choose the right substrate

The substrate selection of the chromium carbide overlay plate directly affects its overall performance. Generally, low-alloy steel or high-strength steel is used as the substrate to provide good mechanical strength and toughness.

2. Optimize the thickness of the chromium carbide layer

The thickness of the chromium carbide layer is a key factor affecting wear resistance. Generally speaking, a thicker chromium carbide layer can provide better wear resistance, but it also increases the manufacturing cost and difficulty. Therefore, the relationship between thickness and economy should be weighed in the design to ensure that the chromium carbide layer can meet the use requirements without excessive waste of materials.

3. Improve welding process

Choosing a suitable welding method (such as argon arc welding, laser welding, etc.) can reduce deformation and cracks in the heat-affected zone and improve bonding strength. At the same time, controlling the welding temperature and speed helps to obtain evenly distributed chromium carbide, thereby improving wear resistance.

4. Strengthen post-processing process

After the chromium carbide composite plate is manufactured, it is also very important to carry out appropriate post-processing processes. Processes such as heat treatment, surface hardening, and shot peening can further improve the hardness and wear resistance of the material. In addition, these processes can also improve the microstructure of the material and increase its service life.

The performance of customized chromium carbide overlay plates can be effectively improved by selecting the right substrate, optimizing the thickness of the chromium carbide layer, improving the welding process, and strengthening the post-processing process. Chromium carbide composite plates are carefully designed to provide excellent wear resistance, making them indispensable in industries such as mining, power generation, and construction. These plates are made by covering a high chromium carbide alloy on a steel base, resulting in a tough and durable product.