Unveiling the Artistry Behind 2L Vinegar Bottle Blow Molds

In the world of manufacturing and processing machinery, the artistry behind creating 2L vinegar bottle blow molds is truly a marvel to behold. These molds play a crucial role in the production of plastic bottles, ensuring precision, durability, and efficiency in the manufacturing process. In this article, we will delve into the intricate details of how these molds are crafted, the materials used, and the expertise required to achieve perfection in every bottle produced. The manufacturing of 2L vinegar bottle blow molds requires a high level of innovation and precision. These molds are designed to create the distinctive shape and size of 2L vinegar bottles, ensuring that each bottle meets the highest standards of quality and durability. The innovation lies in the intricate design of the mold, which allows for the precise shaping and molding of the plastic material to create a seamless and flawless bottle.

Craftsmanship and Expertise in Mold Making

Craftsmanship and expertise are essential components in the creation of 2L vinegar bottle blow molds. Skilled mold makers meticulously design and engineer the molds to ensure that every detail is perfect. From the initial concept and design phase to the final production of the mold, expert craftsmanship is required to achieve the desired results. The expertise of mold makers in understanding the properties of different materials and their behavior during the molding process is crucial in creating molds that produce high-quality bottles consistently.

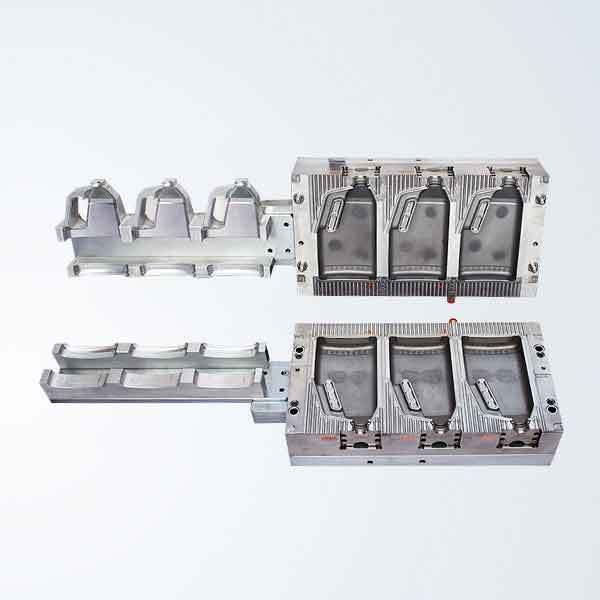

Materials Used in 2L Vinegar Bottle Blow Molds

The materials used in the creation of 2L vinegar bottle blow molds are carefully selected for their durability, heat resistance, and flexibility. High-quality steel, aluminum, and other alloys are commonly used in the construction of these molds to ensure longevity and precision in the molding process. The choice of materials is critical in determining the overall quality and performance of the molds, as they must withstand high temperatures and pressures during the molding process.

Techniques in Mold Making

The techniques used in mold making for 2L vinegar bottle blow molds are highly specialized and require a deep understanding of the molding process. From CNC machining to EDM (electrical discharge machining) and polishing, each step in the mold-making process is crucial to achieving the desired results. Skilled technicians use advanced machinery and tools to shape, cut, and refine the molds to ensure they meet the exact specifications required for producing high-quality bottles.

Quality Control and Testing

Quality control and testing are integral parts of the mold-making process for 2L vinegar bottle blow molds. Each mold undergoes rigorous testing and inspection to ensure that it meets the highest standards of quality and precision. From dimensional checks to stress testing and material analysis, every aspect of the mold is scrutinized to guarantee its performance and longevity in the molding process.

Advancements in 2L Vinegar Bottle Blow Mold Technology

With advancements in technology and materials, the artistry behind 2L vinegar bottle blow molds continues to evolve. Innovative techniques such as 3D printing and computer-aided design (CAD) have revolutionized the mold-making process, allowing for greater precision and efficiency in producing molds. These advancements have led to higher productivity, reduced lead times, and enhanced quality in the manufacturing of plastic bottles.