Understanding the Mechanisms and Benefits of Sliding Headstock Automatic Lathes

Sliding headstock automatic lathes are a sophisticated category of machining equipment widely used in the manufacturing sector, particularly in the CNC (Computer Numerical Control) field. These machines are engineered to produce high-precision parts with minimal human intervention, making them essential for industries that require mass production of intricate components.

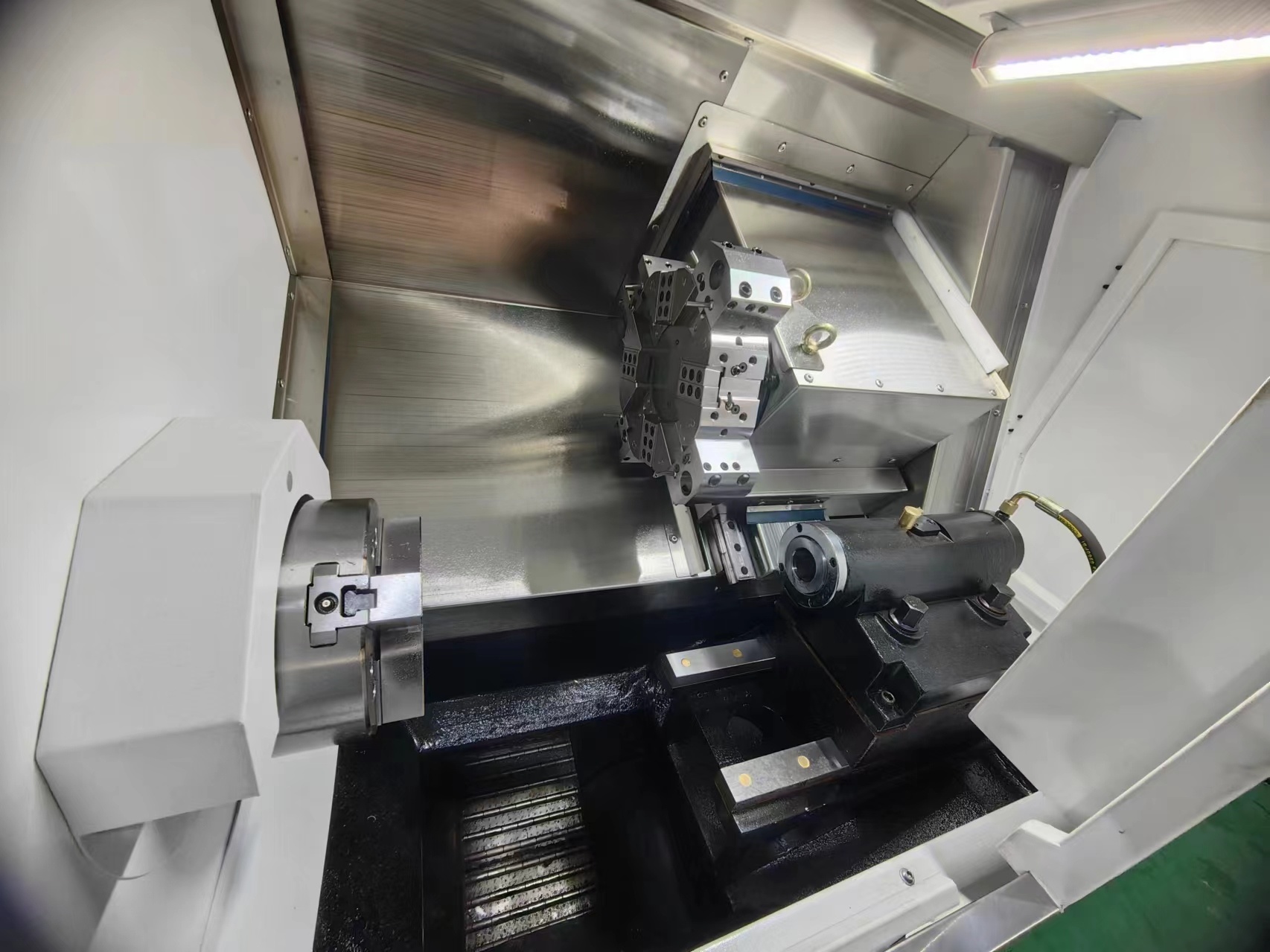

The primary feature of a sliding headstock lathe is its ability to move the workpiece back and forth through the spindle, allowing the cutting tool to engage the material at various points along its length. This movement provides a unique advantage in producing long, slender parts, as it allows for shorter tool overhangs and improved stability during cutting operations. The result is enhanced precision and surface finish, which are critical in applications such as aerospace, automotive, and medical device manufacturing.

One of the significant benefits of sliding headstock automatic lathes is their efficiency. These machines can operate at high speeds and with minimal setup time, leading to increased productivity. The automation aspect reduces the need for manual labor, allowing operators to focus on quality control and other essential tasks. Additionally, the flexibility of these lathes enables manufacturers to switch between different part designs with relative ease, thanks to programmable controls that can adapt to various machining operations.

Another noteworthy advantage is the reduction of waste material. By using sliding headstock technology, manufacturers can optimize the use of raw materials and minimize scrap, which is both economical and environmentally friendly. This is particularly important in today’s manufacturing landscape, where sustainability practices are becoming increasingly prioritized.

Moreover, sliding headstock automatic lathes are often equipped with advanced features such as multi-axis capabilities, which allow for more complex machining operations without requiring multiple setups. This versatility enables the production of intricate shapes and designs, further expanding the range of applications for these machines.

Sliding headstock automatic lathes represent a significant advancement in the field of machining technology. Their ability to produce high-precision, complex parts with efficiency and reduced waste makes them invaluable in modern manufacturing. As industries continue to evolve and demand more precise components, the role of these innovative lathes is likely to grow, solidifying their position as a cornerstone of machining processes across various sectors. Understanding the mechanisms and benefits of sliding headstock automatic lathes can empower manufacturers to optimize their production capabilities and meet the challenges of an ever-changing market.