Understanding Auto Parts Processing: A Comprehensive Guide for Manufacturing and CNC Machining

Auto parts processing is a critical component of the manufacturing and machining industry, particularly in the realm of CNC (Computer Numerical Control) machining. This process encompasses a variety of techniques and technologies used to create, modify, and enhance the components that make up automobiles and other machinery. Understanding the intricacies of auto parts processing can lead to improved efficiency, reduced waste, and higher-quality products.

At its core, auto parts processing involves several stages, including design, material selection, fabrication, assembly, and quality control. The design phase is crucial, as it determines the specifications and tolerances that the final product must meet. Advanced software tools like CAD (Computer-Aided Design) are commonly employed to create detailed blueprints of each component.

Once the design is finalized, the next step is material selection. Different types of materials, such as metals, plastics, and composites, can be used depending on the application and performance requirements. Understanding the properties of these materials is essential, as they influence the durability, weight, and cost of the finished part.

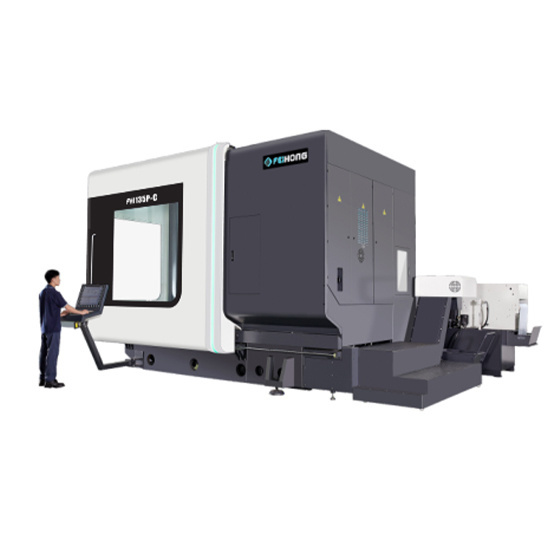

The fabrication stage is where CNC machining comes into play. CNC machines are capable of producing complex shapes and precise dimensions with high repeatability and consistency. Processes such as milling, turning, and drilling are commonly used to transform raw materials into finished parts. The automation provided by CNC technology not only enhances productivity but also minimizes human error, making it a preferred choice in auto parts processing.

Once the components are fabricated, they move on to assembly. This phase may involve the integration of multiple parts into a final product, which could range from engine components to transmission systems. Efficient assembly processes are vital for maintaining production timelines and ensuring that all parts fit seamlessly together.

Quality control is the final step in auto parts processing. Rigorous testing and inspections are conducted to ensure that the parts meet industry standards and specifications. Techniques such as non-destructive testing (NDT) and precision measurement help identify any defects or inconsistencies before the parts are shipped for use in vehicles or machinery.