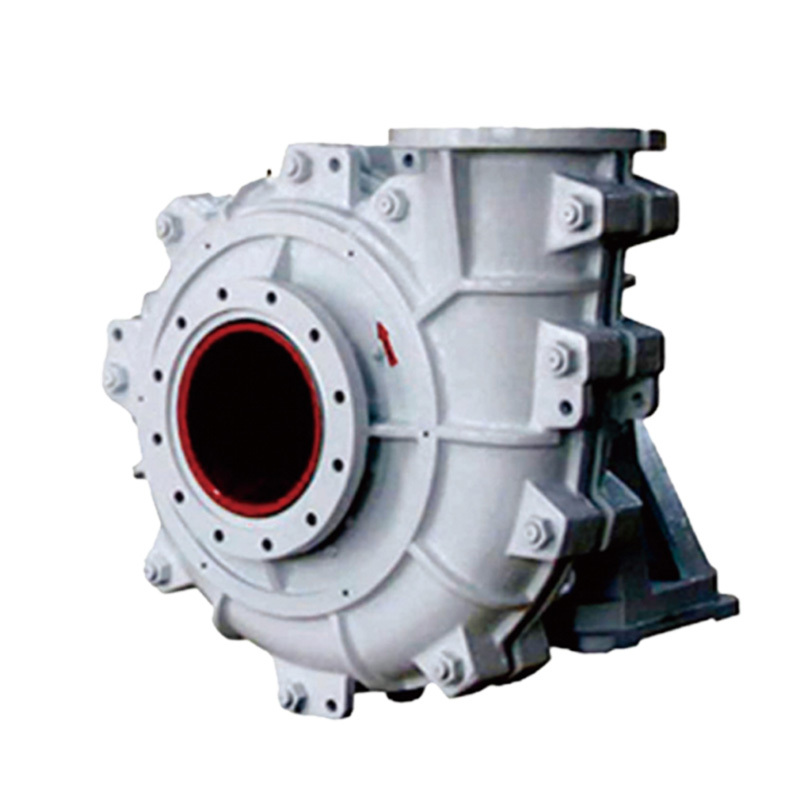

Top Non-Ferrous Mine Slurry Pump Factory: Everything You Need to Know

Non-ferrous mine slurry pump factories play a crucial role in the mining industry, specifically in handling and transporting abrasive and corrosive slurries. These pumps are designed to withstand the harsh conditions of mining operations and ensure efficient and reliable performance.

Key considerations when choosing a non-ferrous mine slurry pump factory include the materials used in the pump construction, such as high-quality corrosion-resistant alloys like stainless steel, titanium, or Duplex steel. It is essential to select a factory that offers a wide range of pump sizes and configurations to meet the specific requirements of different mining applications.

In addition to material selection, factors such as pump design, hydraulic performance, wear resistance, and ease of maintenance are critical in ensuring the longevity and reliability of the pump. A reputable non-ferrous mine slurry pump factory will provide comprehensive technical specifications, performance data, and after-sales support to assist customers in selecting the most suitable pump for their needs.

When it comes to the operation and maintenance of non-ferrous mine slurry pumps, proper installation, monitoring, and regular servicing are essential to maximize pump efficiency and lifespan. Routine inspection of pump components, such as impellers, liners, and seals, is necessary to prevent premature wear and ensure optimal performance.

In conclusion, choosing the right non-ferrous mine slurry pump factory is crucial for the success of mining operations. By considering factors such as material selection, pump design, and maintenance practices, customers can ensure the reliable and efficient performance of their slurry pumps in challenging mining environments.