Maximize Efficiency by Leveraging the Benefits of a Mini CNC Lathe with Bar Feeder

1. Introduction to Mini CNC Lathes and Bar Feeders

In today's fast-paced manufacturing environment, efficiency is paramount. Companies are continually seeking ways to streamline processes and maximize productivity. One effective approach is the integration of mini CNC lathes equipped with bar feeders. These machines not only enhance operational efficiency but also contribute significantly to precision and cost savings. This article explores the numerous advantages of utilizing a mini CNC lathe with a bar feeder, providing a comprehensive overview for manufacturers looking to optimize their production capabilities.

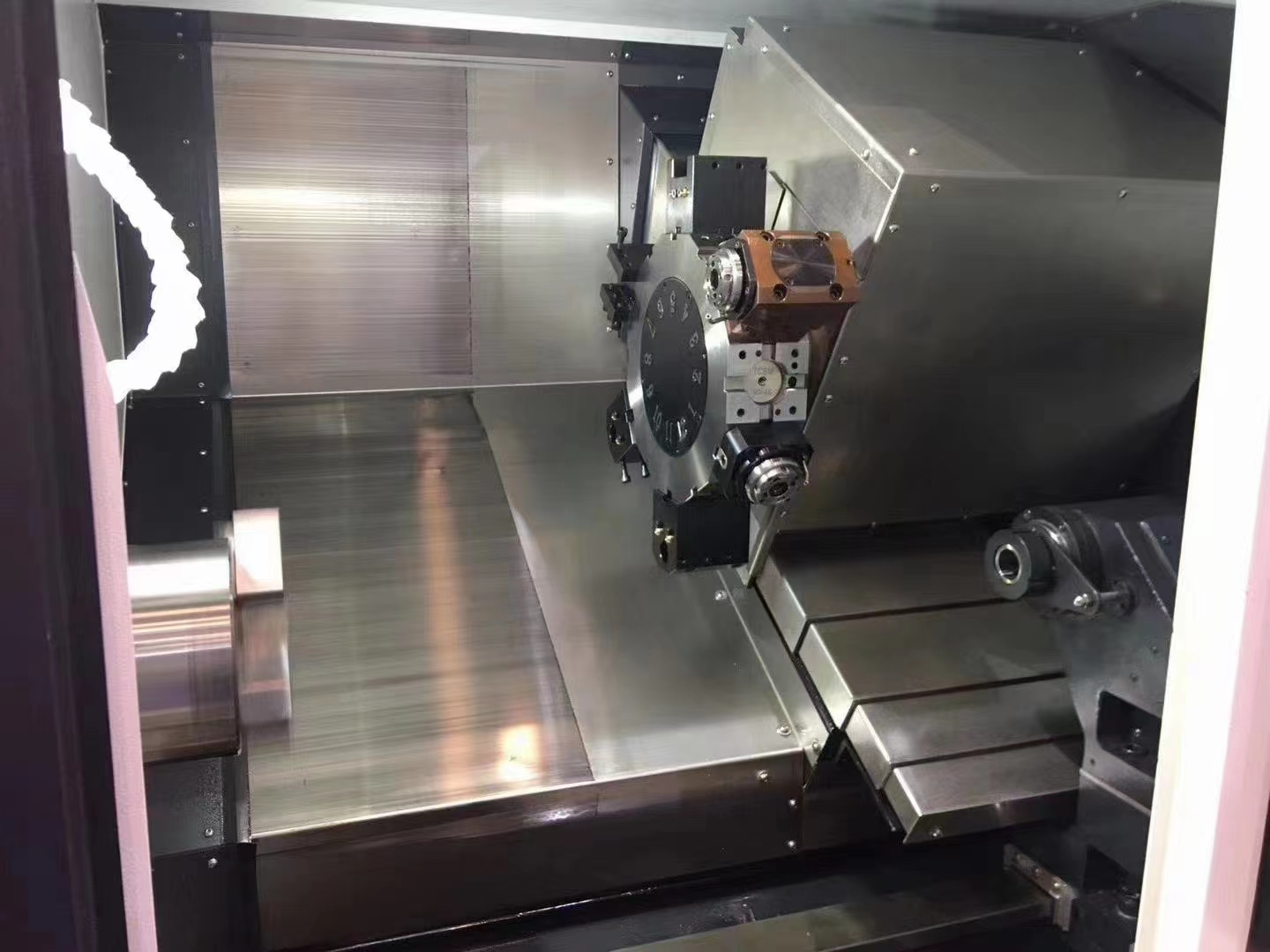

2. What is a Mini CNC Lathe?

A mini CNC lathe is a compact, computer-controlled machine tool designed for turning operations. Unlike traditional lathes, which require manual operation, mini CNC lathes automate the machining process, allowing for greater accuracy and reduced labor costs. They are particularly beneficial for small to medium-sized production runs, where precision and repeatability are critical. The versatility of mini CNC lathes makes them suitable for various materials, including metals, plastics, and composites.

3. Understanding Bar Feeders

A bar feeder is an essential accessory that automates the loading of raw materials into the CNC lathe. This device allows for continuous production by feeding bar stock into the lathe, reducing downtime associated with manual loading. Bar feeders come in various configurations, including automatic and semi-automatic options, catering to different production needs. By implementing a bar feeder, manufacturers can significantly enhance their operational efficiency and throughput.

4. How Mini CNC Lathes Enhance Efficiency

Mini CNC lathes equipped with bar feeders bring several efficiency-enhancing features to the manufacturing process:

4.1 Increased Production Speed

By automating the loading process, mini CNC lathes with bar feeders can operate continuously, resulting in higher production speeds. The ability to handle multiple jobs without interruption minimizes idle time, allowing manufacturers to meet tight deadlines and increase output.

4.2 Reduced Setup Time

The quick-change tooling systems often found in mini CNC lathes enable faster setups for different projects. This feature is especially advantageous for manufacturers that require frequent changes in specifications or designs.

4.3 Streamlined Workflow

Integrating a bar feeder with a mini CNC lathe creates a seamless workflow. The automation of material handling reduces the need for manual intervention, freeing up operators to focus on more complex tasks and improving overall productivity.

5. Benefits of Using a Bar Feeder

The addition of a bar feeder to a mini CNC lathe offers a myriad of benefits:

5.1 Enhanced Productivity

With a bar feeder, manufacturers can load multiple bars of material, allowing for extended machining cycles without interruptions. This continuous operation leads to significant productivity gains.

5.2 Improved Quality Control

Automated feeding systems reduce the risk of human error during the loading process. This consistency leads to better quality control, ensuring that parts meet stringent specifications.

5.3 Flexibility for Various Applications

Bar feeders can accommodate different sizes and types of materials, providing manufacturers with the flexibility to handle a wide range of projects without needing extensive reconfiguration.

5.4 Lower Labor Costs

By automating the feeding process, businesses can reduce their labor costs, as fewer operators are needed to manage the machine. This reduction in workforce translates to significant savings over time.

6. Precision and Consistency in Manufacturing

One of the standout features of mini CNC lathes is their ability to achieve high levels of precision. The integration of advanced technology allows for tight tolerances and intricate designs, which are crucial in manufacturing.

6.1 Precision Engineering

Mini CNC lathes are capable of producing parts with tolerances as tight as +/- 0.001 inches. This precision is essential for industries such as aerospace and medical equipment, where even the slightest deviation can lead to product failure.

6.2 Consistent Output Quality

With automated processes in place, manufacturers can expect consistent product quality across different batches. This reliability enhances customer satisfaction and fosters long-term business relationships.

7. Cost-Effectiveness of Mini CNC Lathes

Investing in a mini CNC lathe with a bar feeder can lead to substantial cost savings for manufacturers:

7.1 Reduced Material Waste

The precision of CNC machining minimizes material waste, making it an environmentally friendly option. Manufacturers can optimize their material usage, translating to lower costs.

7.2 Lower Energy Consumption

Compared to larger CNC machines, mini CNC lathes consume less energy, reducing operational costs. Their compact design also means they occupy less floor space, leading to potential savings in facility costs.

7.3 Long-Term ROI

The initial investment in a mini CNC lathe with a bar feeder pays off over time through increased productivity, reduced labor costs, and lower operational expenses. This long-term return on investment makes it a smart choice for manufacturers.

8. Common Applications of Mini CNC Lathes with Bar Feeders

Mini CNC lathes with bar feeders are versatile tools used in various industries:

8.1 Aerospace Components

Manufacturers in the aerospace sector often require precision-engineered parts that can withstand extreme conditions. Mini CNC lathes meet these rigorous demands efficiently.

8.2 Medical Devices

The medical industry relies heavily on high-quality components, and mini CNC lathes ensure that these components are produced with the utmost precision and consistency.

8.3 Automotive Parts

From small fasteners to intricate engine components, mini CNC lathes are widely used in the automotive industry for their ability to deliver high-volume production with precision.