How a High Pressure Booster Pump Can Transform Your Operations

1. Introduction to High Pressure Booster Pumps

In today's competitive industrial landscape, achieving maximum efficiency is crucial. High pressure booster pumps play an instrumental role in enhancing operational performance across various sectors. These specialized pumps amplify the pressure of the fluid, ensuring that it travels effectively through pipelines and systems. By understanding their functionality and advantages, organizations can unlock substantial improvements in productivity and cost-effectiveness.

2. Understanding the Importance of Pressure in Industrial Applications

Pressure is a fundamental element in fluid dynamics. It directly impacts the flow rate, velocity, and delivery of liquids, gases, and slurries in industrial processes. Inadequate pressure can lead to inefficiencies, wasted energy, and compromised product quality.

2.1 The Role of Pressure in Fluid Dynamics

A proper understanding of pressure allows engineers and operators to optimize system designs, whether it involves transporting water, chemicals, or other substances. High pressure is essential for overcoming friction losses in pipes and ensuring that materials reach their destination without delay.

2.2 Common Applications Requiring High Pressure

Industries such as manufacturing, oil and gas, food processing, and pharmaceuticals often rely on high pressure systems. For instance, in the food industry, high pressure processes can enhance food preservation, while the oil sector requires pressure to efficiently extract resources from deep underground.

3. What is a High Pressure Booster Pump?

A high pressure booster pump is designed to increase the pressure of a fluid before it moves through a system. These pumps are crucial in applications where the existing pressure is insufficient for operational needs.

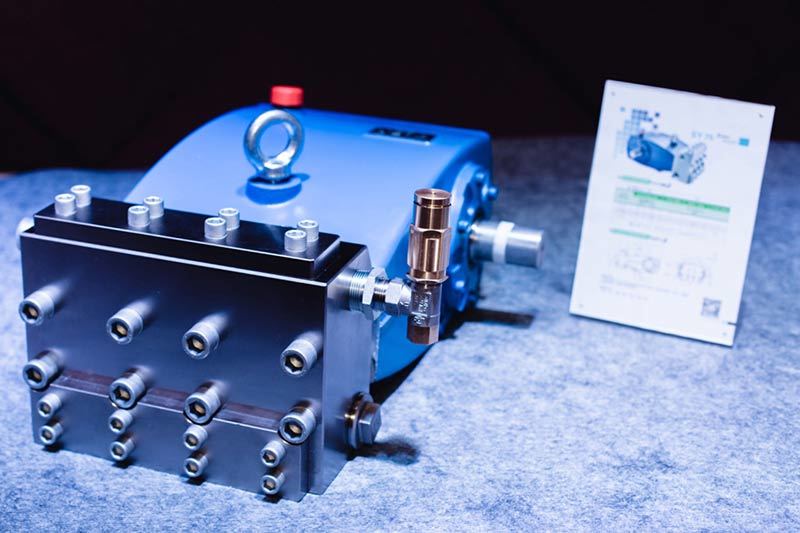

3.1 Key Components of a Booster Pump

Booster pumps typically consist of several key components, including:

- Impellers: These rotate to add energy to the fluid, increasing its pressure.

- Casing: The outer shell that contains the impellers and guides the fluid flow.

- Motors: Drive the impellers, delivering the necessary force.

3.2 Types of High Pressure Booster Pumps Available

There are various types of high pressure booster pumps, such as:

- Centrifugal Pumps: Utilize rotational energy for fluid movement.

- Positive Displacement Pumps: Move fluid by trapping a fixed amount and forcing it into the discharge pipe.

4. Benefits of Using High Pressure Booster Pumps

Investing in high pressure booster pumps offers numerous benefits that can significantly enhance operational efficiency.

4.1 Enhanced Efficiency and Productivity

By maintaining optimal pressure levels, these pumps ensure that processes run smoothly, reducing downtime and increasing overall productivity. In scenarios where fluid delivery is critical, such as in cooling systems or chemical processing, high pressure pumps guarantee consistent output.

4.2 Cost Savings through Energy Efficiency

High pressure booster pumps are designed to minimize energy consumption while maximizing performance. This efficiency translates to lower operational costs and reduced environmental impact. Choosing energy-efficient models can lead to substantial savings over time.

4.3 Improved Fluid Delivery and Consistency

With a high pressure booster pump, fluid consistency is enhanced, resulting in better product quality. In applications like irrigation or fire suppression systems, reliable fluid delivery is paramount to meet operational demands.

5. Selecting the Right High Pressure Booster Pump

Choosing the correct high pressure booster pump can be a daunting task, given the variety of options available. Here are some essential factors to consider.

5.1 Factors to Consider

- Flow Rate Requirements: Understand the required flow rates for your application.

- Fluid Characteristics: Different fluids may require specific pump designs based on viscosity and temperature.

- System Compatibility: Ensure the pump is compatible with existing system components.

5.2 Common Mistakes to Avoid

- Neglecting Pump Specifications: Always review the manufacturer’s specifications to avoid mismatching pumps with applications.

- Underestimating Maintenance Needs: Regular maintenance is vital for ensuring longevity and efficiency; neglecting it can lead to failures.

6. Installation and Maintenance Best Practices

Proper installation and maintenance are critical for the longevity and efficiency of high pressure booster pumps.

6.1 Installation Guidelines

- Ensure Proper Alignment: Misalignment can cause excessive wear; ensure the pump and motor are aligned correctly.

- Follow Manufacturer Instructions: Always refer to the installation guidelines provided by the pump manufacturer.

6.2 Routine Maintenance Tips

- Regular Inspections: Conduct frequent inspections to identify potential issues before they escalate.

- Lubrication: Ensure that all moving parts are adequately lubricated to prevent friction-related damage.

7. Case Studies: Real-World Applications of High Pressure Booster Pumps

Several industries have successfully integrated high pressure booster pumps to enhance their operations:

1. Manufacturing Sector: A leading automotive manufacturer implemented booster pumps in their painting process, significantly reducing drying times and improving finish quality.

2. Food Processing: A dairy processing plant utilized high pressure booster pumps to maintain consistent flow rates, enhancing product quality and reducing production downtime.

High pressure booster pumps are pivotal in enhancing the efficiency and productivity of industrial operations. By understanding their significance, benefits, and best practices for selection and maintenance, organizations can make informed decisions that lead to substantial operational improvements. Investing in the right high pressure booster pump is not just about meeting current demands; it’s about positioning your business for future success, ensuring you stay ahead in a competitive market. Embrace the transformative potential of high pressure booster pumps, and unlock new levels of efficiency in your operations.