Understanding the Importance of LSR Injection Molds in Plastic Molding

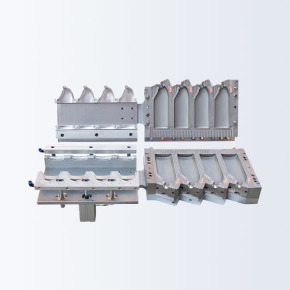

LSR injection molds, also known as Liquid Silicone Rubber injection molds, are specifically designed for the production of silicone rubber products. These molds are essential in the plastic molding industry due to their ability to produce high-quality, intricate parts with precision and efficiency.

One key advantage of LSR injection molds is their durability and longevity. These molds are built to withstand high temperatures and pressures, making them ideal for producing a wide range of silicone rubber products. Additionally, LSR molds offer excellent resistance to wear and tear, ensuring consistent and reliable performance over time.

Another important aspect of LSR injection molds is their versatility. These molds can be customized to suit the specific requirements of each project, allowing manufacturers to create complex shapes and designs with ease. This flexibility makes LSR molds a popular choice for a variety of industries, including automotive, medical, and consumer goods.

In terms of production efficiency, LSR injection molds are known for their high precision and repeatability. This allows manufacturers to achieve consistent results with minimal waste, reducing overall production costs and increasing profitability. Furthermore, the smooth surface finish of parts produced with LSR molds eliminates the need for additional finishing steps, saving time and resources.

LSR injection molds are a critical component in the plastic molding process, offering unparalleled precision, durability, and efficiency. By leveraging the benefits of LSR molds, manufacturers can enhance their production capabilities and deliver high-quality products to meet the demands of today's competitive market.