The Benefits of Investing in Multi-Purpose Machine Tools

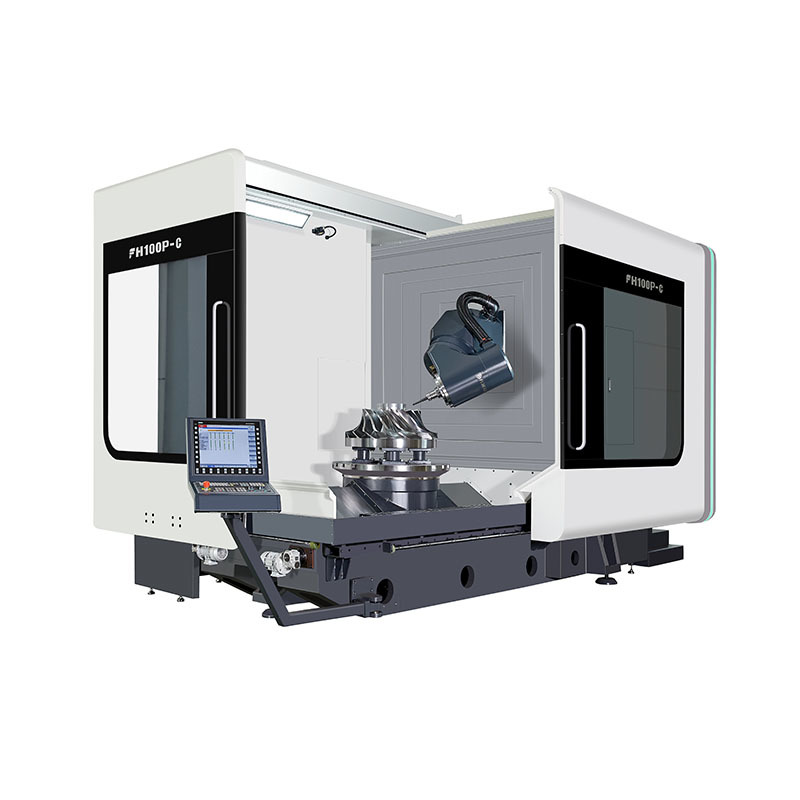

Multi-purpose machine tools combine several functions into one unit, enabling operations such as turning, milling, drilling, and tapping without the need for multiple machines. This versatility not only simplifies the manufacturing process but also reduces the overall footprint of the equipment in the workshop.

The evolution of multi-purpose machine tools is a response to the increasing demand for efficiency and productivity in manufacturing environments. These machines can adapt to various materials and specifications, making them suitable for a wide range of industries, including aerospace, automotive, and electronics.

Key Benefits of Multi-Purpose Machine Tools

Cost-Effectiveness

Investing in multi-purpose machine tools can significantly reduce capital expenditures. Instead of purchasing individual machines for each operation, a single multi-purpose unit can handle multiple tasks, leading to substantial savings in initial investment. Furthermore, lower maintenance costs contribute to long-term financial benefits, as fewer machines mean less upkeep and potential downtime.

Space Efficiency

Manufacturing facilities often grapple with space constraints, making it challenging to house multiple machines. Multi-purpose machine tools require less floor space, allowing manufacturers to optimize their production layout. This space-saving advantage not only frees up valuable real estate but also enhances workflow efficiency by minimizing the distance between operations.

Increased Productivity

The ability to switch between tasks seamlessly allows for faster turnaround times. Multi-purpose machine tools reduce the need for tool changes, setups, and workpiece transfers, leading to improved productivity. By minimizing idle time and maximizing operational efficiency, manufacturers can meet production goals more effectively.

Flexibility and Adaptability

In an industry characterized by rapid technological advancements and changing customer preferences, flexibility is paramount. Multi-purpose machine tools can be quickly reconfigured to accommodate new products or modifications, enabling manufacturers to stay ahead of the curve. This adaptability allows manufacturers to respond swiftly to market demands, ensuring they remain competitive.

Applications of Multi-Purpose Machine Tools

The applications of multi-purpose machine tools are diverse and span across various industries. In automotive manufacturing, for instance, these tools can be used for machining engine components, transmission parts, and chassis elements. In aerospace, they handle precision components that demand high accuracy and quality.

Moreover, multi-purpose machine tools are invaluable in prototyping and small-batch production. Their flexibility allows manufacturers to experiment with different designs without the need for extensive tooling changes, fostering innovation and creativity in product development.

Choosing the Right Multi-Purpose Machine Tool

When selecting a multi-purpose machine tool, several factors should be considered to ensure optimal performance and return on investment.

1. Assessing Your Needs: Evaluate your production requirements, including the types of materials you will be working with and the specific operations you need to perform.

2. Machine Specifications: Look for machines that meet your operational criteria in terms of size, power, and precision. Check the compatibility with your existing production systems.

3. Brand Reputation: Invest in reputable brands that offer reliable customer support and service. Research reviews and seek recommendations from industry peers.

4. Cost Analysis: Consider not only the purchase price but also the long-term operational and maintenance costs of the machine.

5. Future-Proofing: Choose machines that are capable of integrating with future technologies, such as automation and Industry 4.0 solutions, to ensure longevity and relevance.

The Future of Multi-Purpose Machine Tools

As technology continues to advance, the future of multi-purpose machine tools looks promising. Innovations such as smart manufacturing, IoT integration, and advanced robotics are set to enhance the capabilities of these machines further.

Embracing these technological trends will not only improve efficiency but also open new avenues for productivity and innovation. Manufacturers who invest in the latest multi-purpose machine tools will likely find themselves at a competitive advantage, positioning themselves as leaders in their fields.