Painting Production Lines Enhancing Efficiency and Quality in Manufacturing

Painting production lines are essential for industries that require high-quality surface finishing. These systems streamline the painting process, making it more efficient and consistent. In a typical manufacturing environment, painting is a crucial step that significantly impacts the aesthetic appeal and durability of products. Understanding the functioning of painting production lines can offer valuable insights into how to optimize this process.

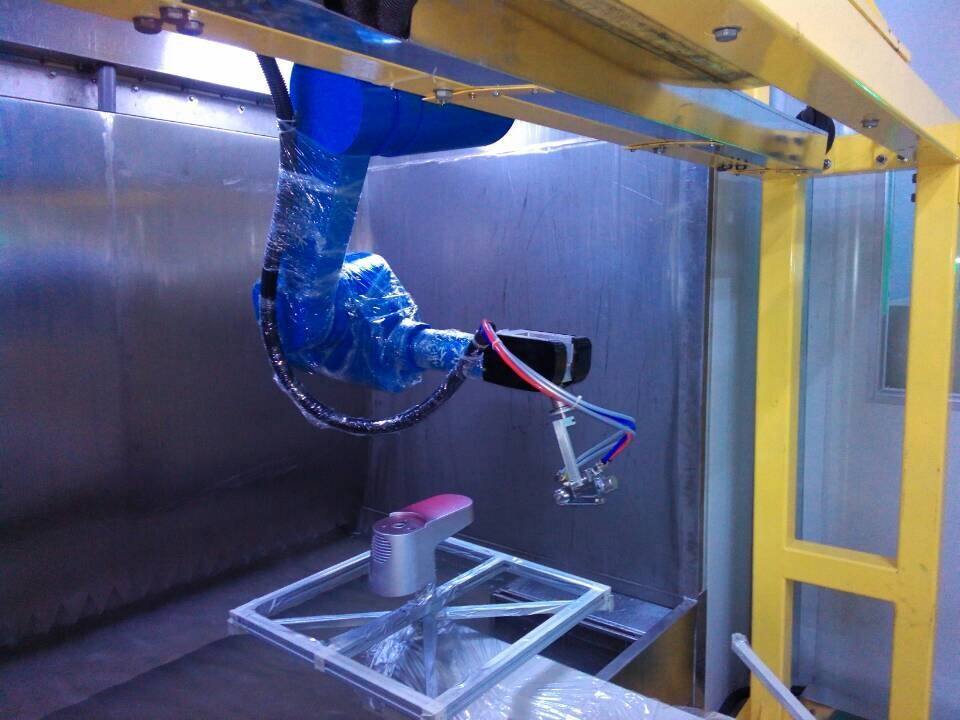

At the core of a painting production line is the automation technology that facilitates various stages of painting, including surface preparation, application of paint, and drying. Modern painting production lines often incorporate conveyor systems that transport items through different stations, ensuring a smooth and continuous workflow. This automation reduces labor costs and human error while increasing output rates.

Surface preparation is a critical first step in the painting process. It involves cleaning the object to remove dust, grease, and other contaminants that may affect adhesion and the final finish. Techniques such as sandblasting or chemical cleaning are commonly employed to prepare surfaces for painting. Once prepared, the items move to the painting station, where different application methods—such as spraying, brushing, or dipping—can be used depending on the type of paint and the desired finish.

After the paint is applied, the drying stage is crucial for achieving the best results. Paint that is not adequately dried can lead to issues such as runs, drips, or poor adhesion. Painting production lines often utilize drying ovens or curing stations that control temperature and airflow to facilitate quick and even drying. Some advanced systems even incorporate infrared curing technology, which enhances efficiency and reduces drying times.

Integration of quality control measures throughout the painting production line is vital for ensuring that the final products meet industry standards. Regular inspections and automated systems can help detect issues in real-time, allowing for timely adjustments and interventions. This proactive approach minimizes waste and ensures that only the highest quality products reach the market.

In conclusion, painting production lines play a pivotal role in modern manufacturing, enhancing both efficiency and the quality of surface finishes. By understanding the components and processes involved, manufacturers can make informed decisions about implementing or upgrading their painting systems. Optimizing these lines not only leads to cost savings but also improves customer satisfaction by delivering superior products. Whether you are involved in automotive, furniture, or any other industry requiring painting, investing in an efficient painting production line can significantly enhance your operational performance.