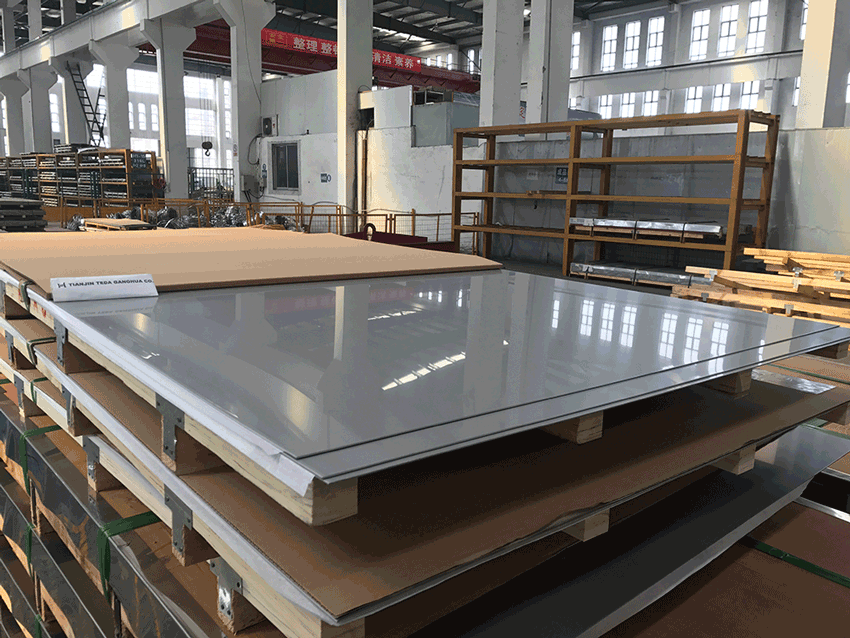

Nitronic 40 stainless steel Plate 0.5 mm 1mm 2mm 3mm 5mm thickness

Good price and quality 0.5 mm thin stainless steel sheets is a stainless steel plate with a thin thickness, usually between 0.3 mm and 3 mm. It has excellent corrosion resistance, good processability, and a beautiful appearance, and is widely used in decoration, home appliances, food processing, and other industries.

Surface treatment

The surface treatment of thin stainless steel plate mainly includes the following small points:

1. Polishing treatment, through mechanical polishing or electrolytic polishing to improve the gloss and cleanliness of the plate.

2. Pickling treatment, through pickling to remove the oxide layer on the surface, so as to make it present a uniform metallic color.

3. Passivation treatment, forming a dense oxide film on the surface to enhance its corrosion resistance.

4. Coating treatment, such as spraying, plating, etc., to provide additional protection or decorative effect.

SPECIFICATION

Thickness

0.4- 6mm for 2B cold rolled sheet/coil ;

3.0-16mm for No.1 hot rolled coils;

3.0-100mm for No.1 hot rolled plate ;

Width

1000/1219/1500mm for cold rolled; 1500/1800/2000mm for hot rolled;

Length

Standard length 2000/2438/3000/6000mm or as required;

Strips: width less than 600mm, and common for 2B cold rolled thickness;

0.5 mm steel sheet price

Heat Treatment Process

1. Annealing treatment, by heating to a certain temperature and then cooling slowly to improve the plasticity and toughness of the material.

2. Solution treatment, by heating to a high temperature followed by rapid cooling to obtain a single solid solution organization to improve corrosion resistance.