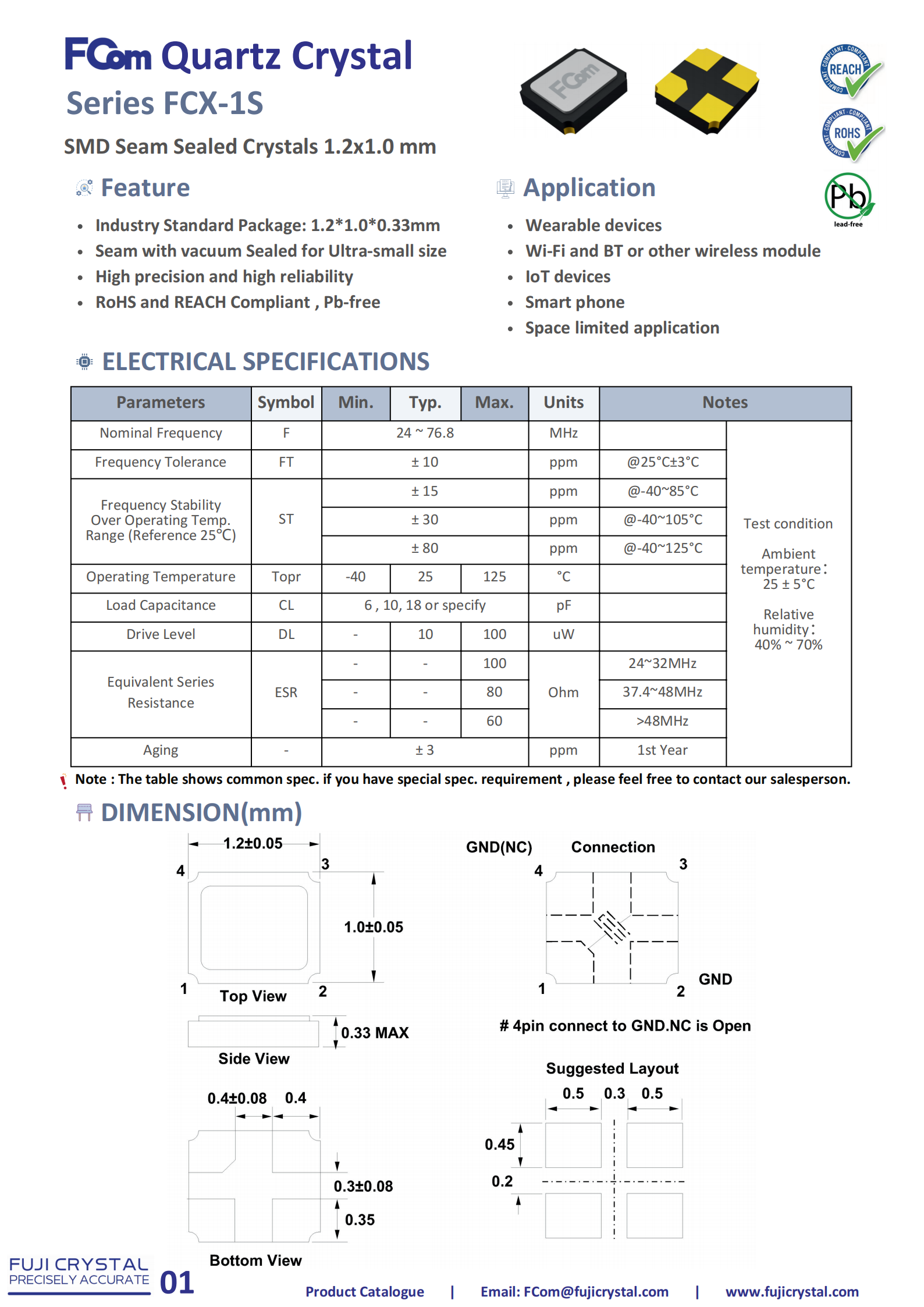

Micro-Miniaturized Crystal Oscillator Technology: Achieving the 1.2mm x 1.0mm

Size and Its Advantages

Challenges in Achieving a 1.2mm x 1.0mm Crystal Oscillator

Material Selection and Cutting Technology Achieving such a small-sized crystal oscillator begins with selecting high-quality quartz crystal material and using precision cutting techniques, such as laser cutting or high-precision mechanical cutting, to ensure uniformity and surface smoothness of the crystal wafer. Given the stringent thickness requirements, this step is crucial for the final product's performance.

Micro-Miniaturized Packaging Technology Packaging technology is one of the core challenges in miniaturization. The 1.2mm x 1.0mm packaging requires advanced techniques like Low-Temperature Co-Fired Ceramic (LTCC) or other micro-miniaturized packaging technologies. These methods allow for integrating the crystal and oscillator circuit in a minimal space while providing robust protection against environmental factors that could impact crystal performance. Additionally, ensuring the packaging's hermeticity is essential for long-term stability and reliability.

Electrode and Bonding Technology Designing and manufacturing micro-sized electrodes and performing precision bonding on such a small crystal is another significant challenge. Techniques like sputtering or electroplating are typically used to form ultra-thin electrode layers on the crystal surface, followed by bonding to the circuit board using methods such as eutectic bonding. This precise manufacturing process ensures reliable electrical connections and mechanical strength.

Frequency Tuning and Testing Due to the small size, frequency tuning requires high-precision techniques like laser trimming or ion implantation to achieve fine frequency adjustments. Every crystal oscillator must undergo stringent automated testing during production to ensure that its performance meets design specifications.

Thermal Management and Reliability Small-sized crystal oscillators are highly sensitive to temperature variations, so design considerations must include ways to minimize thermal effects on oscillation frequency, such as optimizing materials and packaging structure. This design ensures the oscillator's stability and long-term reliability under various temperature conditions.

Advantages of the 1.2mm x 1.0mm Crystal Oscillator

Compact Size This micro-miniaturized crystal oscillator significantly saves PCB space, making it ideal for applications with stringent size constraints, such as wearable devices, ultra-thin smartphones, tablets, and portable medical devices. The small size also facilitates easier integration into complex circuit designs, increasing system integration.

Lightweight Due to its small size, the 1.2mm x 1.0mm crystal oscillator is extremely lightweight, making it highly suitable for weight-sensitive devices like drones, wireless earbuds, and fitness trackers. This reduction in overall device weight enhances the user experience.

High Performance Despite its micro size, this type of crystal oscillator can still provide high-precision, stable frequency output, making it suitable for demanding timing applications such as GPS, wireless communications, and precision instruments. Additionally, due to its small size, these oscillators typically consume less power, making them ideal for battery-powered devices, thus extending product battery life.

Enhanced Adaptability The small size offers greater flexibility for design engineers when laying out circuit boards, allowing for optimized routing and component placement, which can enhance overall system performance and reliability. These oscillators are widely used in micro-sensors, implantable medical devices, and IoT devices, meeting diverse market needs.

Improved Reliability Micro-miniature crystal oscillators typically exhibit excellent vibration and shock resistance, making them well-suited for portable and mobile applications. Moreover, advanced packaging technology ensures the oscillator's long-term stability in harsh environments.

The 1.2mm x 1.0mm micro-miniaturized crystal represents the trend toward the miniaturization of modern electronic components. FCom has introduced the FCX-1S series 1.2*1.0mm ultra-small crystal, specifically designed for modern electronic devices that demand strict size and performance requirements, such as wearable devices, portable medical equipment, IoT devices, and communication systems. Through precise material selection, cutting, packaging, electrode design, bonding, and frequency tuning technologies, this crystal not only achieves significant breakthroughs in size but also offers remarkable advantages in performance, adaptability, and reliability.