Circular Cutting Tools: A Comprehensive Guide

Circular cutting tools are essential in the welding and cutting equipment industry, as they are widely used for various applications such as pipe cutting, metal fabrication, and more. These tools come in different types, including circular saws, hole saws, and rotary cutters, each serving specific purposes in the cutting process.

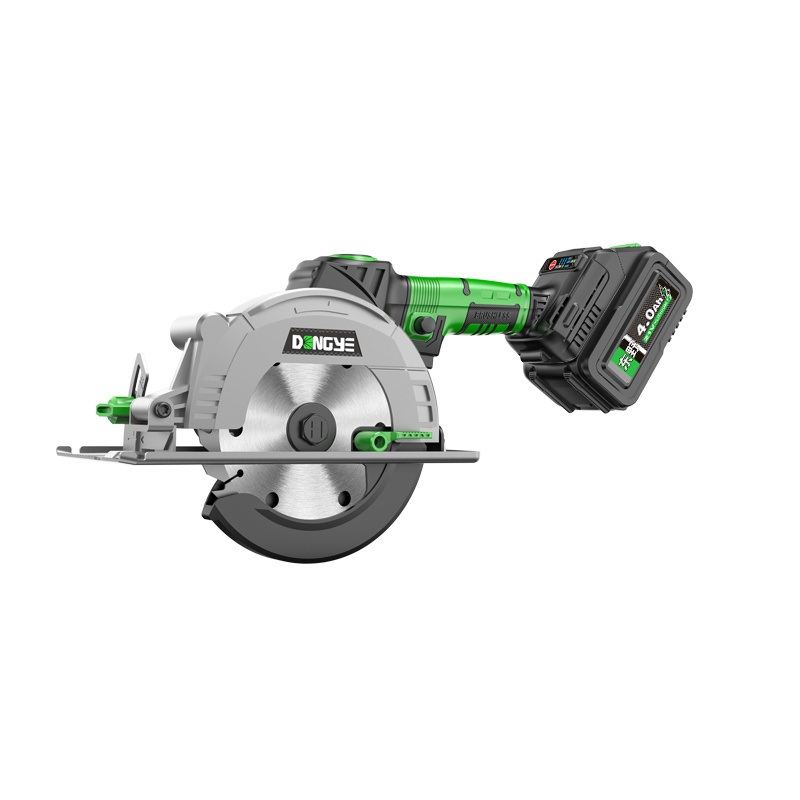

Circular saws are commonly used for straight cuts in materials like wood, metal, and plastic, providing precise and efficient cutting results. Hole saws, on the other hand, are ideal for creating holes in materials, such as pipes and metal sheets, with their sharp teeth and sturdy construction. Rotary cutters are versatile tools that can be used for cutting curves, circles, and intricate shapes, making them suitable for tasks that require precision and flexibility.

To ensure the optimal performance of circular cutting tools, proper maintenance is crucial. Regular cleaning, lubrication, and blade sharpening are essential to prolong the tools' lifespan and maintain their cutting quality. Additionally, following safety precautions while using these tools is paramount to prevent accidents and injuries in the workplace.

In conclusion, circular cutting tools play a significant role in the welding and cutting equipment industry, offering versatility, precision, and efficiency in various cutting applications. By understanding the different types, applications, and maintenance tips for these tools, you can enhance your knowledge and skills in using them effectively for your projects.