All You Need to Know About Overmold Injection Molds in Die Casting and Forging Mold Industry

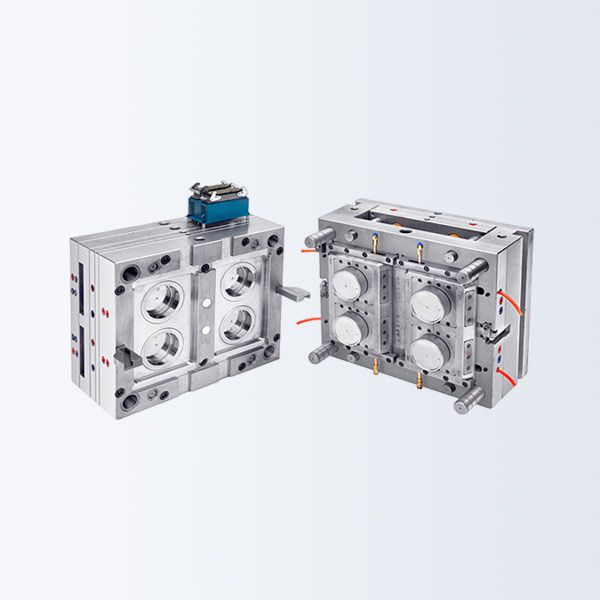

Overmold injection molds play a vital role in the die-casting and forging mold industry, offering unique advantages and applications. In simple terms, over-molding involves injecting thermoplastic material over a pre-existing component, enhancing its functionality and durability. This process is widely used in industries such as automotive, electronics, and medical devices to create products with improved aesthetics, comfort, and performance.

One of the key benefits of overmold injection molds is the ability to combine different materials within a single component. This allows manufacturers to create products with varying levels of hardness, flexibility, and texture, enhancing their overall quality and functionality. Additionally, overmolding can improve the product's resistance to wear, impact, and harsh environments, making it ideal for applications that require durability and longevity.

When it comes to designing overmold injection molds, manufacturers need to consider factors such as material compatibility, mold geometry, and part complexity. Proper design and engineering are essential to ensure the success of overmolding processes and achieve the desired product characteristics. It is crucial to work with experienced mold designers and engineers to optimize the design for manufacturability and cost-effectiveness.

In conclusion, overmold injection molds offer numerous benefits and applications in the die-casting and forging mold industry. By understanding the fundamentals of over-molding and its key considerations, manufacturers can leverage this technology to create innovative products with enhanced performance and aesthetics. If you are looking to explore the possibilities of overmold injection molds in your manufacturing processes, it is recommended to consult with industry experts and leverage their expertise for optimal results.